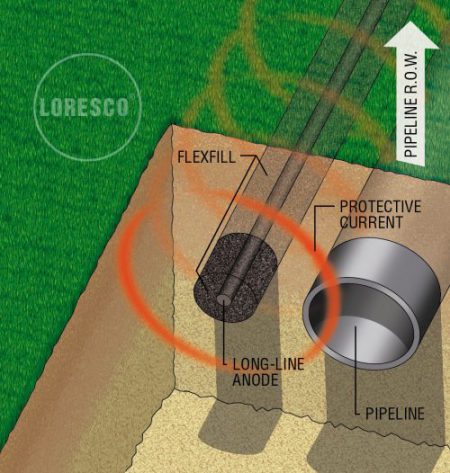

Loresco type FlexFillTM is designed for use around continuous, long-line impressed current anodes. FlexFillTM is the result of extensive laboratory testing combining the rugged requirements of field installation with the demanding performance characteristics required for long-line anodes.

The production of FlexFillTM begins with the critical selection of a base carbon material which meets exacting standards. Calcination of the base material is strictly controlled according to Loresco quality control standards. Sizing of FlexFillTM during the manufacturing process is also carefully controlled to meet the requirements of conductive backfill used with long-line impressed current anodes. All surfaces of FlexFillTM are modified with a conductive coating which maximizes the electronic flow between FlexFillTM and the long-line anode. In effect, this maximizes the life of the anode.

FlexFillTM is a performing backfill medium designed specifically for use with impressed current long-line anodes. Advanced particle selection technology, enhanced surface modifications and rigid production controls all combine to ensure that FlexFillTM surpasses your performance requirements.

Installation:

FlexFillTM is simple to install either by pouring or by subsurface displacement with gravity flow. FlexFillTM has been designed to be placed by either method with no additional steps necessary to create a successful conductive medium. No vibrating nor compacting is required.

Specifications:

- Fixed Carbon: 99.25%

- Ash: 0.25%

- Moisture: 0.50%

- Volatiles (950°): 0.0

- Bulk Density: 68 lbs. per cubic foot

- Particle Shape: Predominantly round

- Particle Surface: All particles are surface modified for maximum electronic conductivity

- Particle Sizing: 90% between 1 mm and 5 mm

- No de-dusting oils are allowed during particle manufacturing.

Shipping:

FlexFillTM is shipped in fifty (50) pound (22.7 kg) coated, woven polypropylene bags. Pallets are available with 50 bags per pallet. Proven export packaging is available. Bulk bags are also available.