The LIDA® Flex Anode integrates our existing product line for impressed current cathodic protection of pipelines and tanks. This system is ideal where the space is limited and the anode is to be installed closed to the cathode (close-by cathodic protection).

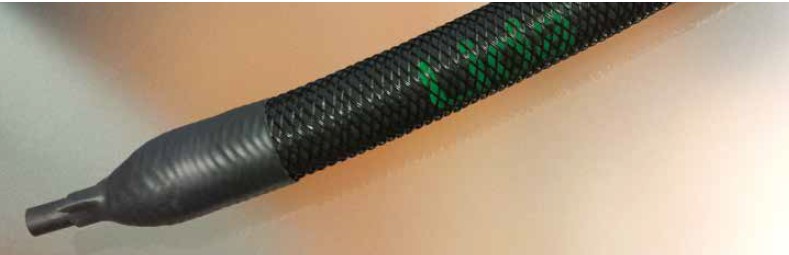

The anode is available with a mesh sock or sleeve that offers protection against anodes to cathode shorts. The system includes backfill in order to optimize current distribution and low groundbed resistance. The core is a precious metal oxide catalyst on a titanium wire substrate.

Available in two different diameters and a standard length of 50 m, the LIDA® anode wire is connected to the header cable at pre-set intervals around the loop. The spacing of the connections is determined at the design stage.

Applications:

• Especially designed for maximum distribution and minimum anode

current attenuation in confined spaces.

• Ideal for distribution of small amounts of CP current on a large

surface area.

• Above Ground Storage Tank Bottoms with secondary containment

liner (new constructions and replacements).

• Parallel Anode Pipeline CP

System strengths and advantages for customers:

• Easy to Install – Cost Effective

• Ready to Lay in Place – Reduced installation time

• Follows Structure Symmetry – maximum CP efficiency achieved by running a continuous anode parallel to the cathode

• 100% Factory Connections – high QC

• Continuous Anode Distribution – Optimized protection current spreading

• Optimized Power Efficiency – Energy saving

• Optimized Low Groundbed Resistance – Suitable to high resistivity environments