“Chill Cast” in Metal Molds

- Assures consistent weight, greater density less flake graphite grain boundary, and lower chemical segregation than Sand Cast Anodes.

- ANOTEC Chill Cast structure is similar to “Spin Cast” Tubular Anodes.

- Independent laboratory tests confirm that Anotec Anodes withstand drop impact tests to more than twice the height of Sand Cast Anodes.

- ISO 9001 Quality Control assures: chemistry (by spectrometer), impact strength and production lot traceability.

- Accelerated Corrosion Tests confirm that Anotec Chill Cast anodes perform significantly better (up to 19%) than Sand Cast anodes in chloride and sulphate environments. Test reports available on request.

- Spherical Tip prevents hang-up when lowering into deep wells.

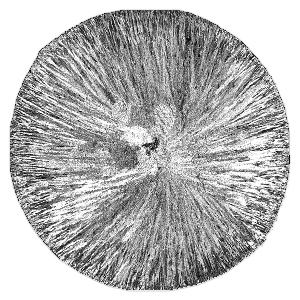

A dense skin of minute columnar grains and a dense core of equiaxial grains. Occasionally, very fine interdendritic porosity at center. Predominantly spheroidal shaped graphite. Similar to the structure of vacuum refined High Silicon Iron.

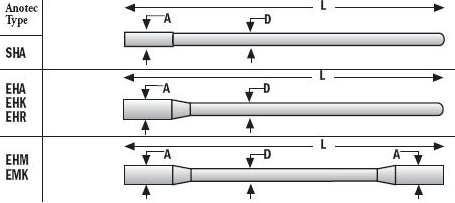

| Anotec Type | D(in.) | L(in.) | A(in.) | Weight(lbs.) | Area(ft.²) | Anodes/Crate | Gross lbs. |

|---|---|---|---|---|---|---|---|

| SHA | 2 | 60 | 2.2 | 43 | 2.6 | 50 | 2300 |

| EHA | 2 | 60 | 3 | 44 | 2.7 | 50 | 2350 |

| EHM | 2.1 | 60 | 3 | 60 | 2.8 | 45 | 2850 |

| EHK | 1.5 | 60 | 2.2 | 26 | 2 | 70 | 1970 |

| EMK | 1.5 | 60 | 2.2 | 27 | 2.1 | 60 | 1770 |

| EHR | 3 | 60 | 4 | 110 | 4 | 24 | 2790 |