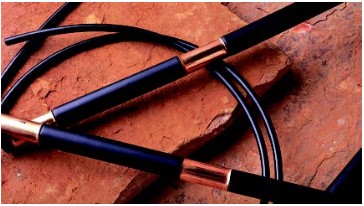

LIDA® tubular anodes are titanium tubes with a mixed metal oxide coating. The mixed metal oxide is a crystalline, electricallyconductive coating that activates the titanium and enables it to function as an anode.

The mixed metal oxide anode has an extremely low consumption rate, measured in terms of milligrams per ampere-year. As a result of this low consumption rate, the tubular dimensions remain nearly constant during the life of the anode providing a consistently low resistance anode.

Whether operating in soil, freshwater, mud, or seawater, LIDA® mixed metal oxide coatings demonstrate very high chemical stability even in environments with very low pH values. Unlike other impressed current anodes, the LIDA® coatings are not affected by the generation of chlorine.

Benefits

• Dramatically reduces cable costs

• Reduces handling and installation costs

• Lower cost per amp-hr

• Guaranteed electrical contact and moisture seal integrity

• Consistently low resistance anode

Features

• Multi-anode conductor

• Lightweight / durable

• High current output

• Patented crimp connections

• Dimensionally stable

Applications

• Groundbeds

Deep

Shallow Vertical

Horizontal

Open Hole

• Marine

Sea Water

Brackish Water

Mud

• Fresh Water

LIDA® “anode string” is comprised of electrical cable threaded through one or more tubular anodes. Electrical connection between the anode and cable is via a patented, mechanical crimping process. The crimp connection is likewise utilized to seal the anode around the cable at both ends.

Since only a single cable lead protrudes from the hole, the junction box is eliminated when using a LIDA® string — reducing the cost of materials and labor. String assemblies are also available in a looped configuration with two tails, or as multiple, staggered strings for system redundancy and maximum current distribution throughout the groundbed.

We recommend the use of quality, conductive, carbonaceous backfill, a vent pipe and Ventralizers™, suitable cable, good design practices, and understanding.

Advantages

LIDA® Crimp – Many impressed current anodes are connected to the cable with resin-based seals, which may develop cracks or lose adhesion to the cable or the anode. Moisture penetration also may occur, resulting in loss of electrical contact. LIDA® anodes are connected with a special crimping process which improves the life of the tubular anode system.

On the surface, the crimp on the ends and in the middle appears the same. Yet they serve different purposes and are made differently. The center crimp makes electrical contact with the cable while the end crimps form a moisture resistant seal. Electrical connection between the tubular anode and the power cable wire is achieved by sliding the tube onto the cable and crimping a section of the tube at mid-length around a stripped portion of the cable.

Both ends of the tubular anode are sealed over the insulated cable by applying 50 tons of hydraulic pressure. This crimping process eliminates the need for mastic or resin sealants.

Reliability – In choosing the LIDA® tubular anode, you have selected the most durable and reliable product in the industry for your cathodic protection needs. LIDA®tubular anode strings are backed by a five-year, no hassle warranty. Design, assembly and installation factors have been carefully considered so that your time and costs are minimized as much as possible.

Ease Of Installation – The LIDA® anode-cable assemblies are easy to handle, transport and install because of their unique flexibility. It makes your on-site job easier as well.