SPECIAL EXPANDED PTFE GASKET FOR HIGH TEMPERATURE STEAM AND HOT WATER APPLICATIONS, 450 DEG. F. AND LOWER. RAISED FACE RING GASKETS ARE STANDARD. FULL FACED GASKETS, AND FLANGE BOLTS AND NUTS CAN BE FURNISHED UPON REQUEST.

PRODUCT DESCRIPTION

*FlANGE KITS ARE AVAILABLE IN 15~, 30~. AND 600# CLASS SIZES

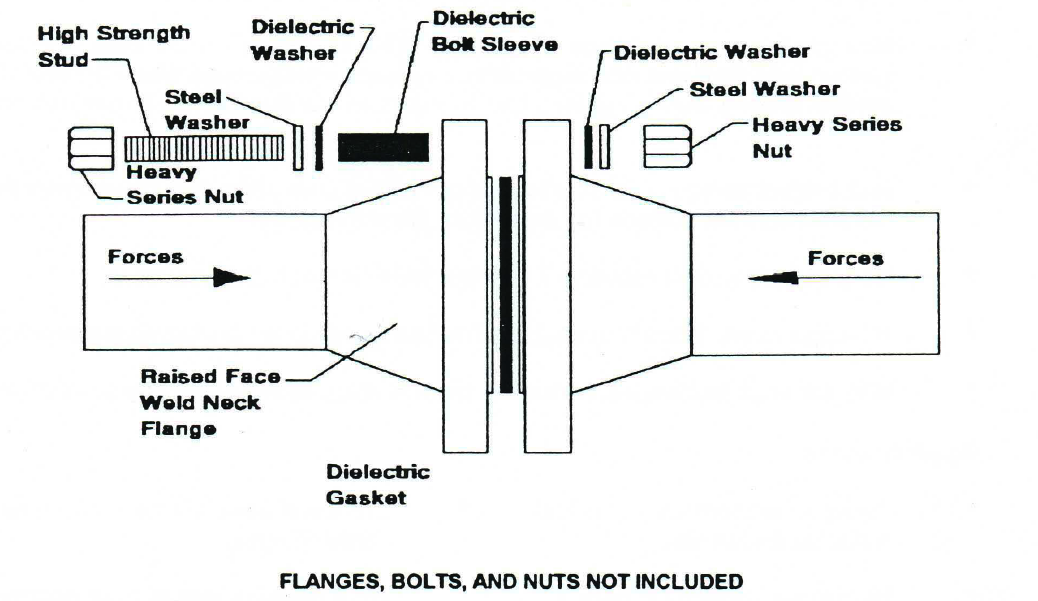

*ALL FLANGE INSULATION KITS INCLUDE A DURABLE NEW TECHNOLOGY COMPOSITE

TEFLO~ RING GASKET THAT IS RATED AT 500 DEG. F.,

*A 1/32 IN. THICK NOMEX PAPER TUBE SLEEVE FOR EACH BOLT,

*A COMPLETE SET OF 1/8 IN. DOUBLE G-7 AND STEEL WASHERS,

*INSTRUCTION SHEETS FOR PROPER KIT INSTALLATION

Expanded PTFE Gaskets:

Advantages:

*Operating temperature range: Maximum Temperature 500 Oeg. F. Maximum Pressure 2000 PSIG

(Operating temperature and pressure may not be compatible at the same time)

*Suitable for cryogenic environments (-321 Deg.F)

*Highly compressible. Manufactures torque chart accompanies each kit.

*Has good creep resistance. Standard PTFE is subject to cold flow. Expanded PTFE resists cold flow and has high torque retention properties. Memory flexibility resists leaking during cycling. Confonns to minor flange face imperfections.

*Not subject to aging. Not affected by nonnaI environmental conditions. Follow installation instnJctions for maximum life expectancy.

*Very wide chemical resistance range. Inert to most an chemicals

*FDA approved. Does not,support bacterial growth or contaminate product in pipe

*Win not stick to flanges. Releases from surface allowing for low cost maintenance

Applications:

*Cathodic protection electrical isolation flange kits.

*Fiberglass reinforced flange connections.

*Criogenic flange connections

*Heat Exchanger flanges with dissimilar metals

*Electrical isolation between dissimilarmetal flanges.

*Food process flange connections.

*Steam Vessel Ranges.